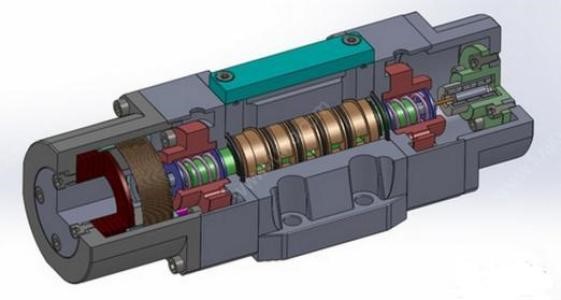

Hydraulic Cylinder Seamless Pipe

Hydraulic cylinder seamless steel pipe e loketse oli, silinda ea hydraulic, ts'ebetso ea mochini, phala e teteaneng ea lebota, indasteri ea lik'hemik'hale, matla a motlakase, indasteri ea boiler, mocheso o phahameng, mocheso o tlase le ho hanyetsa kutu e seamless phala ea tšepe, 'me e loketse peterole, sefofane, ho qhibilihisa, lijo, ho boloka metsi, matla a motlakase, indasteri ea lik'hemik'hale, fiber ea lik'hemik'hale, mechine ea bongaka le liindasteri tse ling.

Ka lebaka la khatello ea kelello e setseng e setseng karolong e ka holimo ea hydraulic cylinder, ho molemo ho koala mapetsong a manyenyane a holim'a metsi le ho sitisa ho atoloha ha khoholeho.Kahoo, ho hanyetsa kutu ha bokaholimo ho ka ntlafatsoa, 'me ho ka lieha ho hlahisa kapa ho atolosoa ha mokhathala, kahoo matla a mokhathala a quilted tube a ka ntlafatsoa.Ka ho etsa rolling, ho thehoa lera le thata la mosebetsi o batang holim'a metsi, e leng ho fokotsang elasticity ea sefahleho sa ho sila.

Ka hona, ho hanyetsa ho roala ha lebota le ka hare la quilting tube ho ntlafatsoa 'me ho chesoa ho bakoang ke ho sila ho qojoa.Ka mor'a ho koloha, ho fokotseha ha bokaholimo ba bokaholimo ho ka ntlafatsa thepa e ts'oanang.

Rolling ke mofuta oa machining oa mahala, o sebelisang deformation ea polasetiki ea tšepe ka mocheso oa kamore ho batalatsa ho se leka-lekane ha karolo e nyane ea sebaka sa mosebetsi, e le ho fetola sebopeho sa bokaholimo, thepa ea mochini, sebopeho le boholo.Ka hona, mokhoa ona o ka finyella ka bobeli ho qeta le ho matlafatsa ka nako e le 'ngoe, e leng ho ke keng ha khoneha ho sila.

Ho sa tsotelehe hore na ho sebelisoa mokhoa oa mofuta ofe, ho tla lula ho e-na le matšoao a sa tšoaneng a lisebelisoa holim'a likarolo, ho fella ka litlhōrō le liphula tse tsitsitseng,

Rolling processing molao-motheo: ke mofuta oa ho qeta khatello, e sebelisang litšobotsi tse batang tsa polasetiki tsa tšepe mocheso oa kamore, 'me e sebelisa khatello e itseng holim'a sebaka sa mosebetsi ka ho roala lisebelisoa ho etsa hore tšepe e holim'a workpiece e hlahise phallo ea polasetiki. 'me u tlatse ka sekoting sa pele se tlase sa concave, e le ho fokotsa bokaholimo ba mosebetsi.Ka lebaka la deformation ea polasetiki ea tšepe e pota-potiloeng, sebopeho sa holim'a metsi se bata 'me lithollo li fetoha hantle, li etsa lera le teteaneng la fibrous le ho etsa lera le setseng la khatello ea kelello.Boima le matla a holim'a metsi li ntlafatsoa, ka hona, ho hanyetsa ho apara, ho hanyetsa kutu le ho lumellana ha sebaka sa mosebetsi ho ntlafatsoa.Rolling ke mokhoa oa ho itšeha oa polasetiki o sa lefelloeng.

Melemo ea phala ea tšepe e se nang seam bakeng sa hydraulic cylinder:

1. The roughness holim'a ka fihla RA ≤ 0,08 & micro;M.

2. Ovality e ka ba ≤ 0.01mm.

3. Ho thatafala holim'a metsi ho eketsoa ho felisa deformation ea khatello ea kelello, 'me boima bo eketseha HV ≥ 4 °.

4. Ka mor'a ho sebetsa ka mechine, ho na le lera le setseng la khatello ea kelello, 'me matla a mokhathala a eketseha ka 30%.

5. E ka ntlafatsa boleng bo ts'oanang, ea fokotsa ho roala le ho lelefatsa bophelo ba tšebeletso ea likarolo, empa litšenyehelo tsa ho sebetsana le likarolo li fokotsehile.

Ntlafatsa mokhathala o matlagth ea phala e koetsoeng.

Ntlafatsa ho hanyetsa ha lebota le ka hare la phala e kentsoeng.

1. The roughness holim'a ka fihla RA ≤ 0,08 & micro;M.

2. Ovality e ka ba ≤ 0.01mm.

3. Ho thatafala holim'a metsi ho eketsoa ho felisa deformation ea khatello ea kelello, 'me boima bo eketseha HV ≥ 4 °.

4. Ka mor'a ho sebetsa ka mechine, ho na le lera le setseng la khatello ea kelello, 'me matla a mokhathala a eketseha ka 30%.

5. E ka ntlafatsa boleng bo ts'oanang, ea fokotsa ho roala le ho lelefatsa bophelo ba tšebeletso ea likarolo, empa litšenyehelo tsa ho sebetsana le likarolo li fokotsehile.

E sebelisoa bakeng sa maro, li-boilers, liphaephe tse phahameng tse se nang moeli bakeng sa li-boilers, khatello e phahameng ea lisebelisoa tsa manyolo, ho cheka ha geological, ho cheka oli, ho phunyeha ha oli, li-collar tsa ho cheka oli, li-axle tsa likoloi, likepe.

Ha ho bapisoa le phetisetso ea mochini le phetisetso ea motlakase, phetiso ea hydraulic e na le melemo e latelang:

1. Likarolo tse fapaneng tsa phetisetso ea hydraulic li ka hlophisoa ka mokhoa o bonolo le ka mokhoa o bonolo ho latela litlhoko.

2. Boima bo bobebe, boholo bo nyane, inertia e nyane ea motsamao le lebelo la karabelo e potlakileng.

3. Ts'ebetso e bonolo le taolo, e ka hlokomelang taolo ea lebelo e se nang mohato ka mefuta e mengata (taolo ea taolo ea lebelo ho fihla ho 2000: 1).

4. Tšireletso e feteletseng e ka etsoa ka boomo.

5. Ka kakaretso, oli ea diminerale e sebelisoa e le mokhoa oa ho sebetsa, sebaka se lekanyelitsoeng se tsamaeang se ka tšeloa ka boeona, 'me bophelo ba tšebeletso bo bolelele;

6. Ho bonolo ho elelloa motsamao oa mola/

7. Ho bonolo ho hlokomela boiketsetso ba mochini.Ha taolo e kopantsoeng ea electro-hydraulic e amoheloa, eseng feela tekanyo e phahameng ea ts'ebetso ea ho laola ka mokhoa o itekanetseng e ka phethahalang, empa le ho laola hole ho ka phethahala.