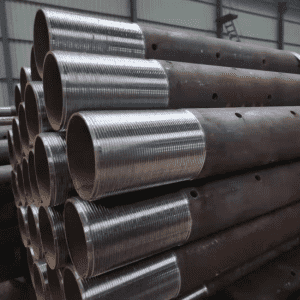

Ts'ebetso ea Pipe ea tšepe

The pin shaft ke mofuta oa fastening e tloaelehileng, e ka ts'oaroang ka mokhoa o tsitsitseng le ho hokahanngoa, kapa e ka tsamaisanang le karolo e hokahaneng.E sebelisoa haholo-holo bakeng sa lenonyeletso la hinge la likarolo tse peli ho theha khokahanyo ea hinge.Hangata pin shaft e notletsoe ka pini e arohaneng, e ka tšeptjoang mosebetsing le ho le bonolo ho e qhaqha.

Tekanyetso ea ASTM e bolela hore matla a tensile a tšepe ea 1040 ke 600MPa, matla a tlhahiso ke 355MPa, bolelele ke 16%, phokotso ea sebaka ke 40%, 'me matla a ts'usumetso ke 39J.

1040 tšepe ke thepa e tloaelehileng bakeng sa likarolo tsa shaft mme e sebelisoa haholo ho etsa mochini.Tšepe ena e na le thepa e ntle ea mochini ebile e theko e tlase.Empa sena ke tšepe ea carbon e mahareng, 'me ts'ebetso ea eona ea ho tima ha e ntle.1040 tšepe e ka thatafatsoa ho HRC42 ~ 52.Ka hona, haeba ho hlokahala hore ho be thata holim'a metsi 'me ho lakatseha lisebelisoa tse phahameng tsa 1040 tsa tšepe, holim'a tšepe ea 1040 hangata e tima (ho tima kapa ho tima ka ho toba) ho fumana boima bo hlokahalang ba holim'a metsi.

Alloy structural tšepe e kang 5140 e loketse likarolo tsa shaft ka mokhoa o nepahetseng oa bohareng le lebelo le phahameng.Ka mor'a ho tima le ho futhumatsa le ho tima, mofuta ona oa tšepe o na le thepa e ntle ea mochine.

5140 tšepe ke e 'ngoe ea litšepe tse sebelisoang haholo ho etsa metjhini.Ka mor'a ho tima le ho futhumatsa, e na le lisebelisoa tse ntle tsa mochine, mocheso o tlase o matla o matla le kutlo e tlaase.Ho thatafala ha tšepe ho molemo.E ka thatafatsoa ho Ф28~60mm ka ho tima metsi le Ф15~40mm ho tima oli.Ntle le ho tima le ho futhumatsa, tšepe ena e boetse e loketse bakeng sa cyanidation le ho thatafala ha induction.Ts'ebetso ea ho itšeha e betere.Ha boima bo le HB174 ~ 229, machinability e lekanyelitsoeng ke 60%.

4130 tšepe ke tšepe e tlase e nang le alloy Ultra-high-matla.Ka mor'a phekolo ea mocheso, e na le lisebelisoa tse ntle tsa mochine, matla a phahameng, ho tiea ho lekaneng, ho thatafala, ho cheseha, le ho sebetsa le sebopeho, empa e na le khanyetso e tlaase ea kutu le khanyetso ea oxidation.E sebelisoa ka mor'a hore mocheso o fokotsehe kapa o fokotsehe.

4140 tšepe ke tšepe e matla e phahameng ka ho fetesisa e nang le matla a phahameng le ho tiea, ho thatafala hantle, ha ho na bohale bo hlakileng, ho senyeha ho honyenyane nakong ea ho tima, moeli o phahameng oa mokhathala le ho hanyetsa ka makhetlo a mangata ka mor'a ho tima le ho halefa.Tšusumetso e ntle ea matla ka mocheso o tlase, matla a phahameng a creep le matla a mamellang mocheso o phahameng.Tšepe hangata e sebelisa ho tima holim'a metsi ka mor'a ho tima le ho futhumatsa e le moralo oa phekolo ea mocheso.

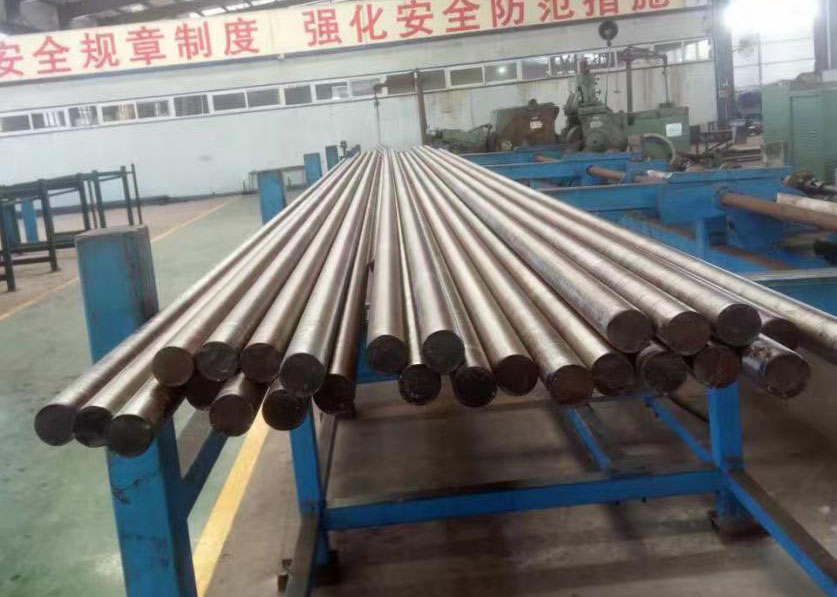

Khamphani ea rona e na le theknoloji e tsoetseng pele e batang le e futhumetseng ea extrusion, e sebetsanang le nts'etsopele le tlhahiso ea likoloi, lithuthuthu, mechini e fapaneng le lisebelisoa tsa motlakase, le lisebelisoa tsa lisebelisoa tsa merafo.

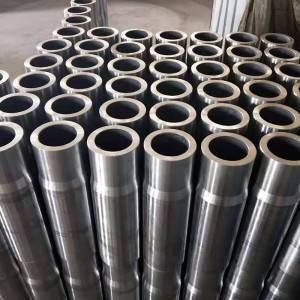

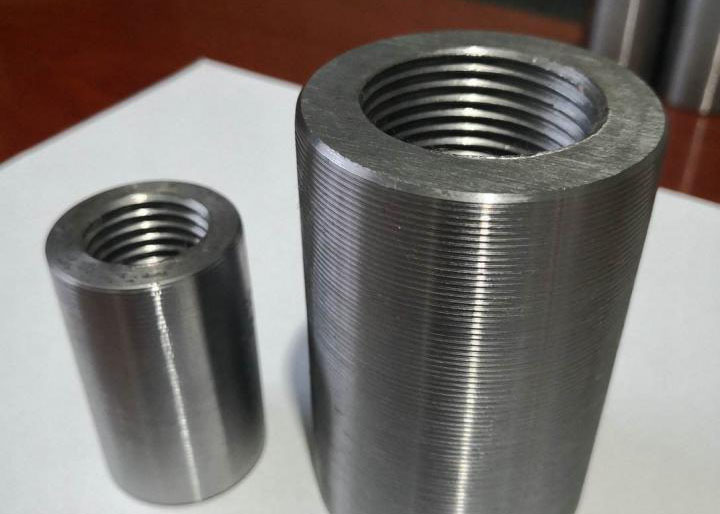

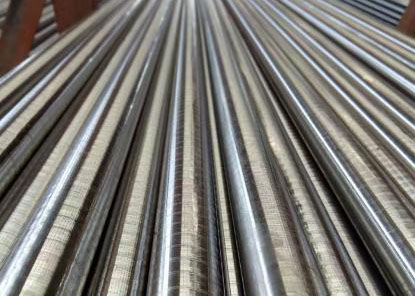

Li-sleeve tsa koloi tse kentsoeng ka har'a koloi, manonyeletso a bokahohleng, li-cylinder blocks, li-axle tse ka pele, li-shafts tse sekoti, li-transmission shafts, li-gear shafts, mefuta e fapaneng ea litulo tsa li-valve, li-pistons tsa mochini oa khatiso oa hydraulic, li-plugs tsa lipeipi tse nang le khatello e matla, lirolara tsa lisebelisoa tsa morafo, Mabili a tataisang. , maoto a sa tšoaneng a tšepe le lihlahisoa tsa alloy aluminium bakeng sa marang-rang a matla a matla a matla, joalo-joalo Likheo tse ka holimo le lihlahisoa tse felileng li ka fanoa.

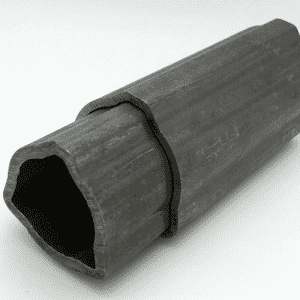

Likarolo tse fapaneng tsa lipolanete, lisebelisuoa tsa letsatsi, likere tsa mehele, lipoleiti tsa mahlakoreng a hlahisoang, li-spline shafts, li-transmission shafts, li-gear plates, li-sleeve tsa spline, 'mele oa meropa le likarolo tse fapaneng tse bōpehileng joaloka likoloi tse batang le li-winch tsa motlakase.Lihlahisoa tse boletsoeng ka holimo tse felileng le tse felileng kaofela li ka fana ka tsona.

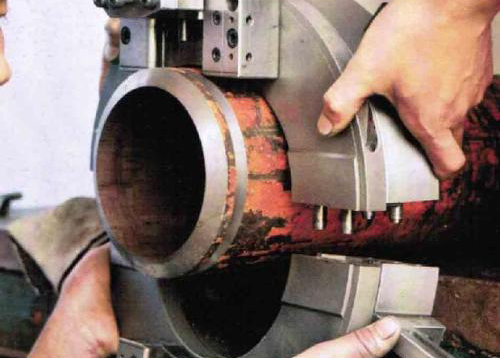

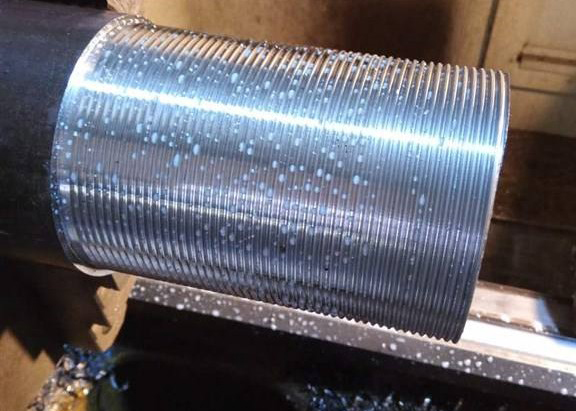

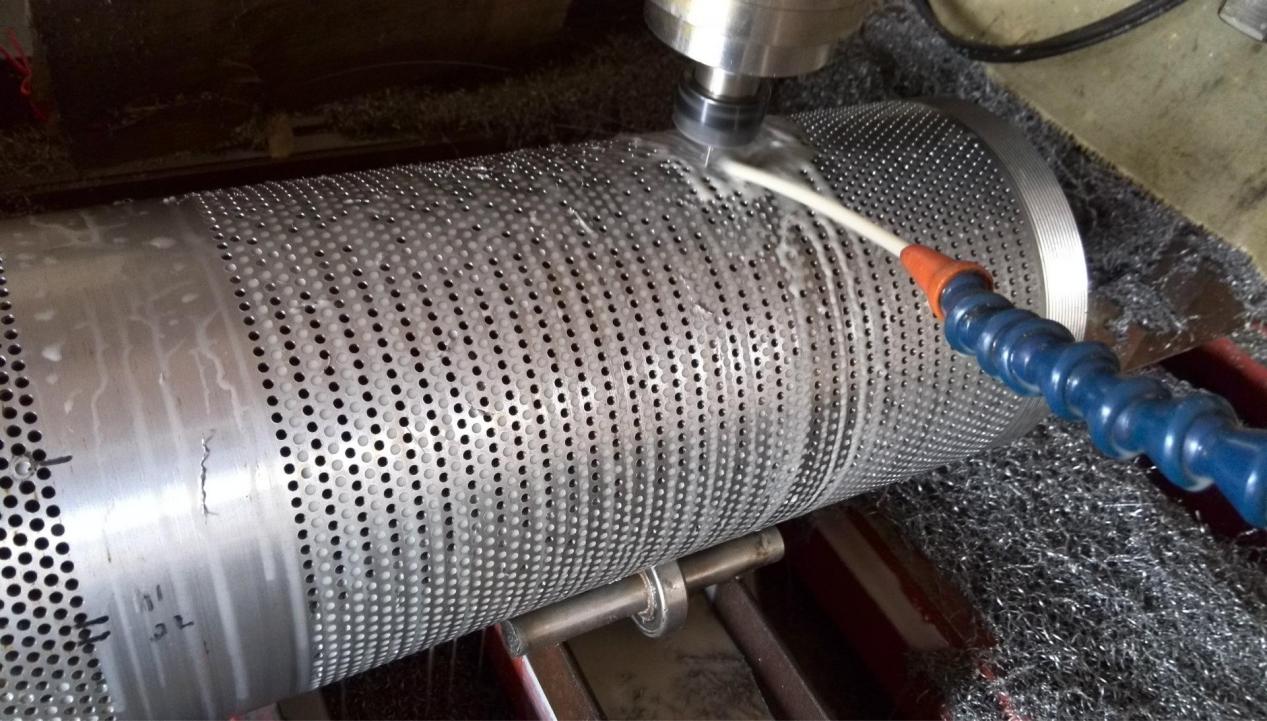

Qha Sekoti

Pipe ea Mosi ea Exhaust